Car interior materials history

In the 1940s, many automotive seat covering fabrics used vinyl or vinylidene chloride, which was dyed with dye under melt conditions, had high color fastness and was easy to clean. At the same time, after the Second World War, nylon began to appear and was used in car decoration along with other materials.

Since the 1950s, fabrics treated with PVC coatings have begun to be widely used in apparel, home decor, and automotive interiors. Because this material can be processed into a variety of different colors, and can be surface molded to achieve different texture effects, it was considered a relatively fashionable composite textile material at that time.

This PVC material has been used in conventional automotive interiors until the 1970s. At that time, people’s living standards have been significantly improved, and the car’s comfort has also been put forward higher requirements. The seat covered with PVC material is very poor in air permeability, especially hot and sticky in the hot summer.

Also from the 1970s, nylon began to be applied to automotive interior fabrics on a large scale with different weave structures and color effects. At the same time, the quality standards for automotive fabrics have also risen to new levels due to increasingly fierce market competition.

Nylon has been used in automotive interiors for nearly 30 years because early car windows were relatively small and the window glass was almost vertical, so the temperature inside the car changed less than the current car under the same daylight conditions. In addition, consumers at the time may pay more attention to the performance of the car, but not very concerned about the interior. Moreover, the early auto market clearly did not have such fierce competition.

Natural leather is used as a high-grade interior material in automobiles. It is much earlier than fabrics. In the early days, it was also lined with fabric as the fabric. The leather surface was usually painted to increase gloss and abrasion resistance, but It also reduces its natural breath-ability. In recent years, due to a large number of legislative provisions on environmental and ecological protection, the leather processing technology has changed a lot.

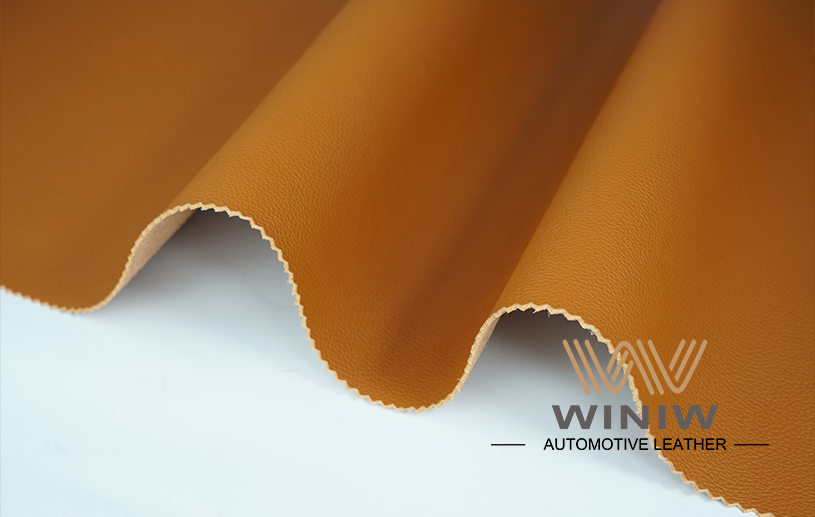

The use of leather in the car, especially in calfskin, is recognized worldwide as a symbol of luxury and noble, but it is expensive and it is estimated that its use will decline in the future. On the one hand, as more and more manufacturers resist the use of animal leather, on the one hand, there are more and more automobile manufacturers. On the other hand, the number of people who raise calves for consumption is decreasing. But people’s enthusiasm for leather is still not reduced, the current method is a combination of leather and fabric used in the car interior. The shortage of leather has led to the resurgence of artificial leather, but the degree of simulation and various technical indicators have been greatly improved. The suede fabrics made of microfibers in fabrics are becoming more and more popular, especially for microfiber leather, which is very popular in the high-end market.