20 Nisan

Araba iç malzemeleri geçmişi

1940'larda, vinil veya viniliden klorür kullanılan birçok otomotiv koltuk kaplama kumaşı, boya ile eriyik koşullarda boyanmıştır., yüksek renk haslığına sahipti ve temizlenmesi kolaydı. Aynı zamanda, İkinci Dünya Savaşı'ndan sonra, naylon başladı…

devamını oku 13 Mayıs

kaynak arıyorum, deri endüstrisi Çin'in geleneksel sütun endüstrisidir. Üretim teknolojisinin araştırılması ve geliştirilmesi ile, suni deri suni deri yavaş yavaş doğal deri statüsünün yerini birçok avantajla almıştır., ve deride ağır bir ürün haline geldi…

devamını oku 20 Şubat

Sanayi konsolidasyonu devam edecek.

Genel rekabet gücü zayıf olan işletmeler, yer değiştirmeyle karşı karşıya kalacak. Otomobil satış sonrası gelişiminin genel eğilimi, marka miktarının azaltılması olacaktır., marka uzmanlığı ve merkezi eğilim açıkken. Çok sayıda tanınmış marka yoğunlaşmıştır.…

devamını oku 14 Şubat

Ocakta 23, 2019, Sunnyvale, Kaliforniya, dünyanın en büyük otomotiv iç tedarikçisi Yanfeng Automotive Interior bugün XiM20 adlı mobil seyahat deneyimi kabinini tanıttı. Bu iç tasarım konsepti, tamamen kendi kendine sürüş paylaşımlı seyahat için tamamen yeni bir kullanıcı deneyimi sağlamak üzere tasarlanmıştır., toplantı…

devamını oku 04 ağustos

Mükemmel performansı nedeniyle, makul fiyat, çevre koruma ve diğer faktörler, mikrofiber deri, günlük yaşamın çeşitli alanlarında giderek daha fazla uygulanmaktadır.. Bugün, mikrofiber derinin çeşitli uygulamaları hakkında konuşacağız. basitçe söylemek gerekirse, mikrofiber deri olabilir…

devamını oku 16 ağustos

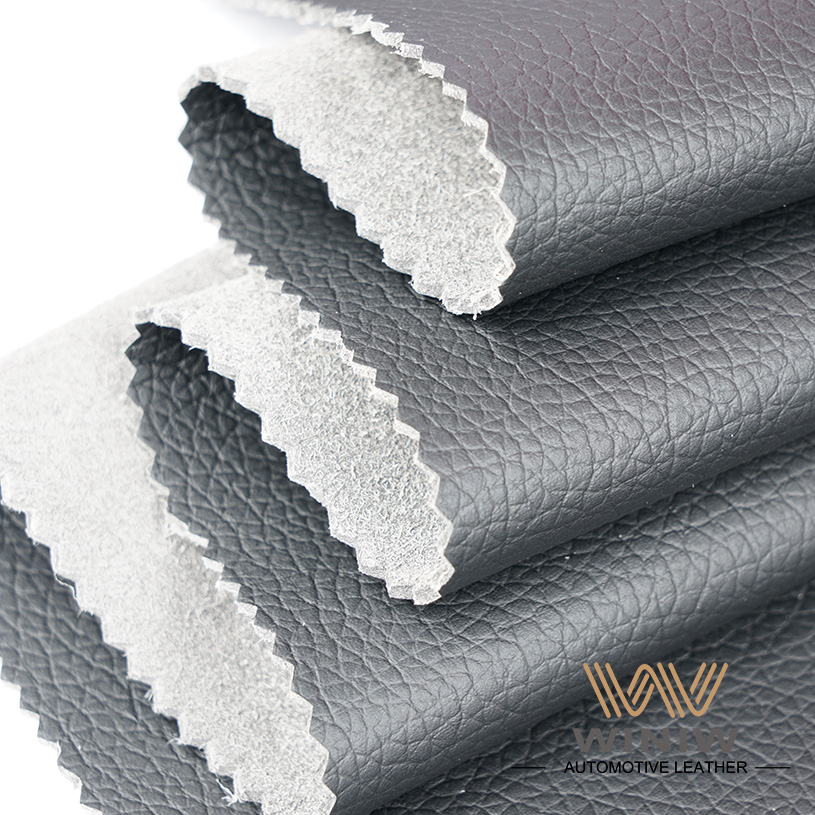

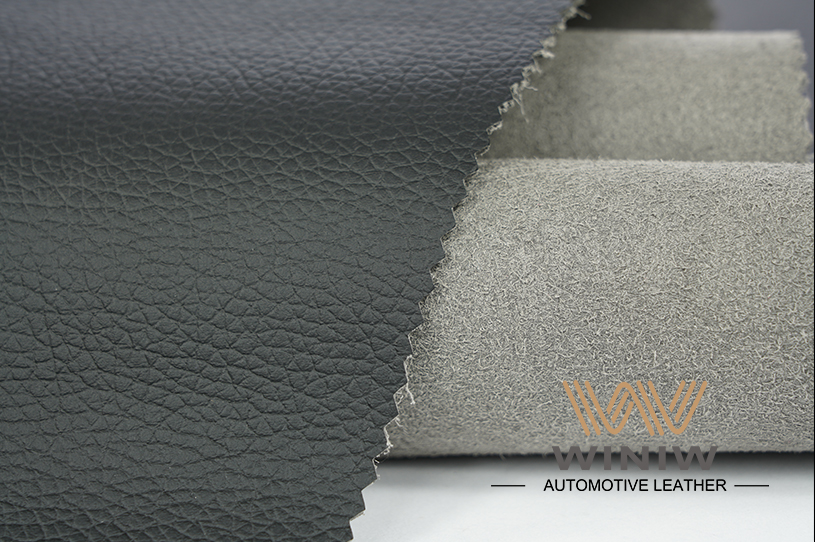

Araba derisi, üretim malzemelerinden scalper araba derisi ve manda araba derisi olarak ikiye ayrılır..

Scalper araba derisi, ince deri tanelere ve yumuşak bir dokunuş hissine sahiptir., manda araba derisi daha sert bir el ve kaba gözeneklere sahipken. Araba deri koltukları yapılır…

devamını oku 23 Nisan

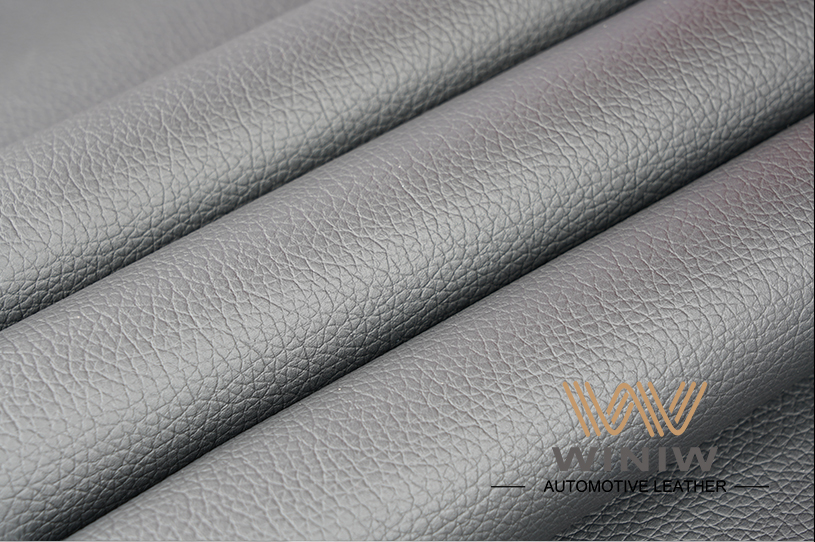

Otomobiller için deri koltuklar genellikle deri ve suni deriden yapılır., biri hayvan derisi, diğeri hayvan derisi olmayan. Deri kesinlikle suni deriden daha pahalıdır, çünkü deri genellikle dana derisinden yapılır, koyun derisi ve domuz derisi. Geçmişte, sadece…

devamını oku 05 ağustos

“Pazarlama Stratejisi ve Tüketici Eğilimleri” temasına odaklanmak, forum Jayne Esteve Cure'u davet etti, Fransız Moda Araştırma Merkezi Başkanı, ve Li Chonggang, Alibaba Tmall Boutique Department Store Genel Müdürü, özel bir konuşma yapmak. Aynı zamanda, Bay….

devamını oku 28 Haziran

Yazın yağmurlu ve nemli, ve mikrofiber derinin korunması küflenmeye neden olmak çok kolaydır. Buna göre, yazın gelmesi mikrofiber derinin saklama sorununun ciddiye alınmasına neden olmalıdır.. Yani, küflenmemek için, ne tür…

devamını oku 04 Haziran

Toyota ve lüks otomobil markası, Lexus, iç endüstride önde gidenler oldular. J.D.Power iç kalite raporunda, Lexus, son altı yılda dört kez birinci oldu. Henüz sonuçlanmış Chicago Otomobil Fuarı'nda, Toyota yeni bir hedef belirledi…

devamını oku