Over the years, an increasingly obvious trend has been to manufacture automotive interior parts from high-quality materials such as leather and artificial leather.

A composite of polyurethane foam or spacer fabric makes leather an attractive soft touch decorative material.

Molding compounding is the standard technique for processing high quality and refined materials. This material, as well as increased production, places high demands on production equipment and processes.

FRIMO offers a variety of composite solutions to ensure that this process requires only a small number of people and is reliable.

The various processes of surface treatment, the application of adhesives, and the actual compounding of leather are integrated into a continuous production process.

Surface treatment

For example, if an injection molded PP instrument panel skeleton needs to be decorated with leather, it must first be surface treated to ensure an inseparable bond with the decorative material.

This process takes place in a separate robotic unit where the surface tension of the plastic is increased by flame treatment of the composite area to prepare for subsequent hot melt application.

Adhesive application

In the next processing stage, a first layer of adhesive is applied to the final part where soft touch is particularly desired. To do this, a 1 mm thick spacer fabric is pressed onto it.

A second layer of adhesive is then applied over the entire surface area to be decorated with leather.

The application of the adhesive is required to be thin and uniform on the surface, in areas where operation is difficult, at the edges, and in the edge pleats.

A multi-axis robot that applies this heated adhesive very finely with a carefully metered amount of air.

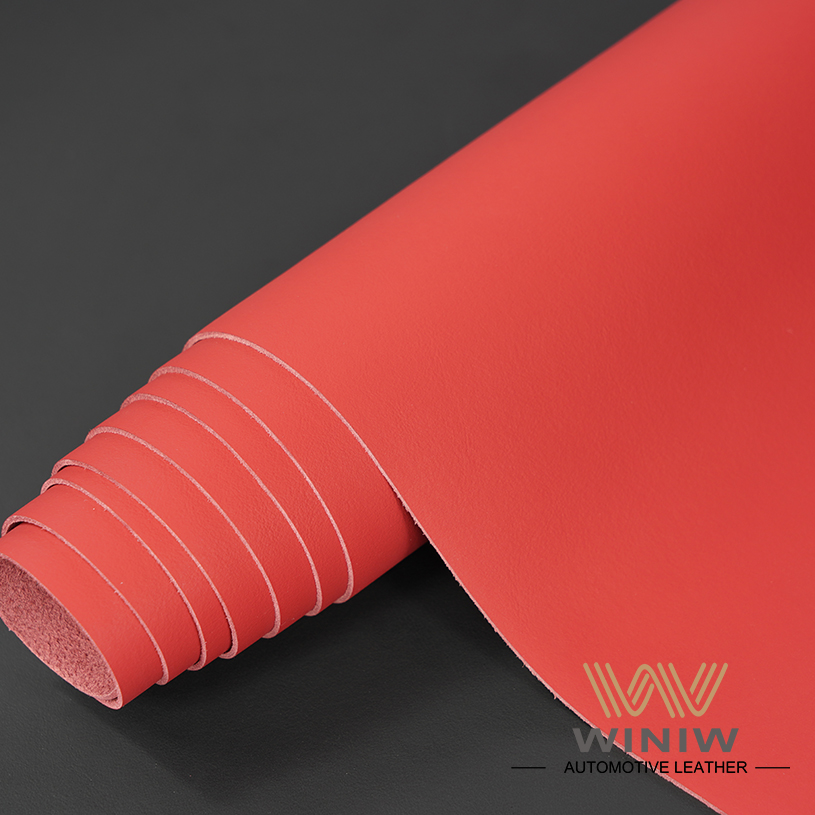

Actual composite of leather

The leather compounding is done in a turntable system.

The carrier member is placed on a rotating table and the leather cover is manually placed on the carrier.

To ensure accurate positioning and seam alignment, the CAD data used is used to accurately create the positioning tool for the sewing thread.

Once the leather cover is in place, automated processing can begin.

With a turntable concept with two stations, you can perform both compression and manual positioning operations.

High levels of automation and reproducibility make it possible to reliably complete medium to high volume production.

The extended tooling and system design allows the left and right hands to simultaneously drive the tooling in the system so that the operator can press the button at any time to quickly and easily replace the product.